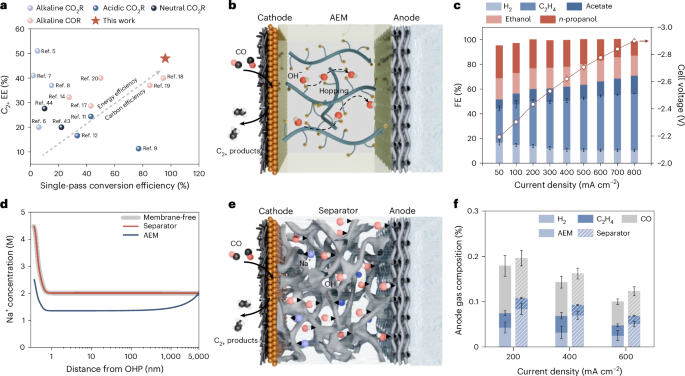

Electrochemical COx reduction to multi-carbon products presents a significant challenge, primarily due to the low energy efficiency associated with traditional electrolysis methods. The sluggish ion transport across charge-selective membranes has been a critical bottleneck, limiting the overall performance of CO electrolysers. Addressing this issue is essential for advancing carbon capture and utilization technologies, which are pivotal in mitigating climate change and achieving sustainability goals. The introduction of a porous, non-charge-selective separator marks a pivotal shift in the design of electrolysers, enhancing ion transport and thereby improving energy efficiency in CO electrolysis processes.

The findings indicate that employing these innovative separators can lead to energy efficiencies of up to 51% for C2+ production, a notable improvement over existing technologies. This advancement not only optimizes the electrolysis process but also has broader implications for the scalability of carbon conversion technologies. By facilitating more efficient ion transport, this approach could significantly lower the energy requirements for COx reduction, making it a more viable option for industrial applications. The integration of such separators could thus accelerate the transition towards sustainable energy systems and contribute to the development of effective carbon management strategies.